Description

Aquaosl I-PurgeX Modular Inflatable Bladder System

I-PurgeX Modular Inflatable Bladder System

About

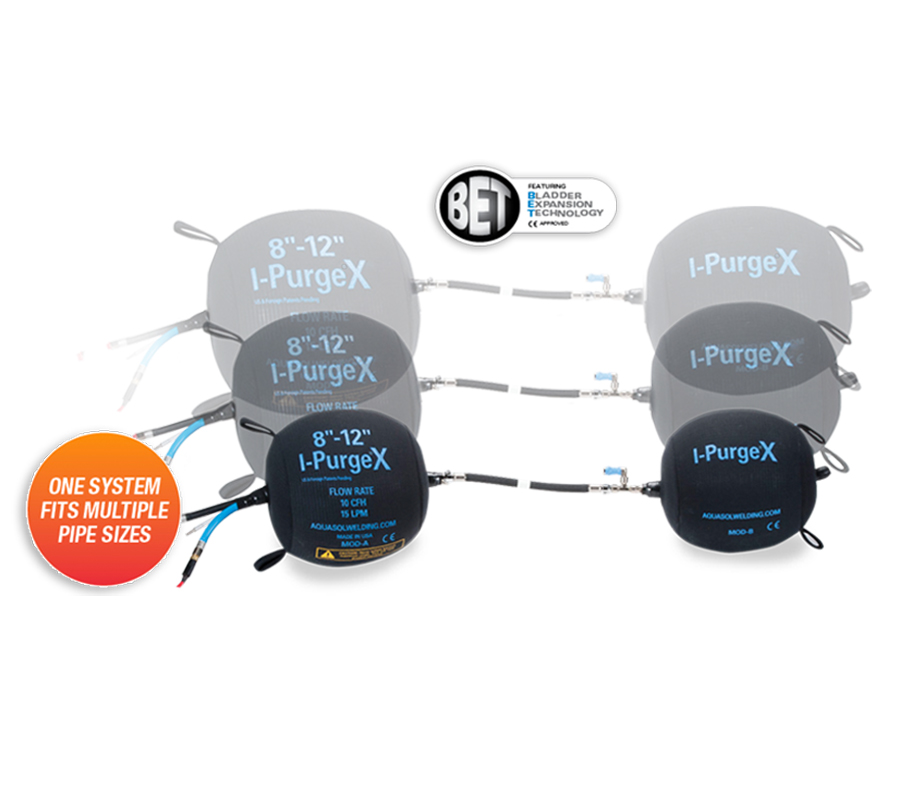

The I-Purge X is the most adaptable and technologically advanced modular inflatable bladder system available to date.

The I-Purge X comes equipped with its revolutionary Bladder Expansion Technology (BET) that enables one unit to fit multiple pipe sizes. Bladders have the ability to expand and contract to fit each piping specification and are protected by a spark resistant exterior cover that does not combust when exposed to flames and sparks.

These state-of-the-art features allow the operator to create multiple configurations, including a one sided pipe stopper and reducer. Bladders are available in sizes ranging from 2″- 3″ (51 mm – 76 mm) to 38″- 48″ (965 mm – 1219 mm) and may be purchased either individually or as a complete system, a distinct advantage should additional sizes be desired or a component need replacing.

Coupled with an extended length, high heat resistant harness; the I-Purge X is the most versatile pipe purging solution available and is ideal for fabrication shops and and any environment with pipe accessibility. Manufactured in the USA from the highest quality materials, the I-Purge X is a reusable, long-term solution that is expandable, extendable, and simply extraordinary.

Features and Benefits

Inflatable Bladders Modules A & B

- Equipped with proprietary Bladder Expansion Technology (BET) that enables one unit to fit multiple pipe sizes and schedules

- Designed to expand and contract numerous times

- Manufactured in the USA from the highest quality materials

- Inflated bladders create an impermeable, air tight seal on pipe wall for multiple inflation dimensions

- Spark resistant, durable exterior cover does not melt

- Heavy-duty interior inflatable bag

- Re-usable, long-term solution for purging multiple pipes of the same diameter

High Heat Extended Length Harnesses

I-PurgeX Modular Inflatable Bladder System

- Internal hose and protective external fiberglass sleeve capable of withstanding high temperatures

- Flexible bridge harness easily navigates through pipes, including elbows and tees over 90°

- Kink resistant hose assures continuous gas supply

- Complete with luminescent indicator for accurate alignment at root gap

- Various lengths of harnesses available to accommodate heat affected zone (HAZ) during pre-heating and high heat applications

- I-Purge X 38″ to 48″ is equipped with a high flow harness to expedite inflation

Quick Connect Interchangeable Fittings

- Push-button feature enables modules to snap-in-place in seconds

- State-of-the-art technology allows for greater versatility and easy assembly – enabling the user to create multiple configurations

- Easy change and replacement of components to avoid costly re-purchase of complete system, with spare parts available for separate purchase

- Corrosion resistant proven lock mechanism for secure connection

Proprietary Relief Valve

- Factory pre-set relief valves allow for precise flow rates while minimizing set-up time and reducing consumption

- Aids in maintenance of optimum seal on pipe wall

- Prevents risk of over inflation

- Low profile relief valve available on 2″ and 3″ model

Inert Gas Diffuser

- Patent-pending technology

- Reduces turbulence by dispersing inert gas equally in all directions within the weld zone, improving weld quality and consistency

Tri-Flow Inner Tubing System (BLUE, BLACK & WHITE Hoses)

Multiple inlet/exhaust ports for faster, more efficient weld purging

Separate Connections:

BLUE– Inflation of Bladders

Initial function is to inflate bladders then flood weld zone with noble gas

BLACK – Gas Distribution Within Weld Zone

Designed to expedite purging, the secondary (BLACK) purge hose is used to flood the weld zone with inert gas and evacuate oxygen at a faster rate

WHITE – Exhaust Connection

Connect this hose to an Oxygen Monitor, such as Aquasol’s PRO OX®-100 that obtains readings down to 100 PPM (0.01%), for continuous or spot monitoring of oxygen in the weld zone

Pull Loops

- Strong pull loops can be connected to a rope or chain to insert or remove the I-Purge X

- It is important that bladders be deflated before insertion or removal

- Moderate tension (approx. 5 lbs.) should be applied on pull-wires to prevent sagging of the harness during installation and operation

Carrying Bag

- When welding is complete, bladders can be deflated, extracted, cleaned and stored in the provided carrying bag

- Carrying bag protects the bladder when not in use from dust and debris in most industrial work environments, prolonging life

I-Purge X Reducer

- Unlike other models with permanent fittings, a pipe reducer can be easily created by either inflating the unit to two different dimensions or simply connecting two bladders of different, yet similar diameters

- Combine different sizes to create unique pipe configurations

I-Purge X Isolator Inflatable Pipe Stopper & Single Purge Bladder

- The I-Purge X Isolator is designed to function as a pipe plug for a wide range of applications, including purging of valves or tanks, as well as non-purging applications such as pipe system sealing for servicing, cleaning and inspection

- Constructed of heavy-duty materials designed to withstand the extreme conditions of the petrochemical, utility and construction industries

I-Purge® Isolator Adaptors:

Make the most out of our modular design!

Convert your I-Purge® two bag systems into one-sided isolators for challenging weld geometry. Both our I-Purge® and I-Purge ®X bladders are convertible with our innovative modular design!

I-Purge® Mod-A Adaptor: A quick connect diffuser for your Mod-A I-Purge® bladder

I-Purge® Mod-B Adaptor: A length of hose with fittings to hook your I-Purge® Mod B bladder to your Argon tank

How I-Purge X Works

I-Purge X Modular System Components: Equipped with the most Advanced Interchangeable Components

1. Module A 5. Quick Connection to Module A 9. Inflation & Purge (BLUE) Hose

2. Module B 6. Relief Valve 10. Luminescent Indicator

3. Quick Connection to Module B 7. Direct Purge (BLACK) Hose 11. Pull Loops

4. Fiberglass High Heat Bridge Harness 8. Exhaust Monitor Connection 12. Gas Diffuser

Quick Instruction Guide

1. Ensure I-Purge X is fully assembled (i.e. modules are securely connected to harness)

2. If necessary, connect rope, chain, or wire to the pull loops on the ends of the bladder modules. This will allow you easy insertion and removal of the system.

3. Connect inert gas lines to the BLUE and BLACK hoses

4. BLUE gas hose is required to inflate the purge bladders

5. BLACK gas hose is optional to expedite the purging process

6. Position the purge unit in the pipe using the luminescent indicator as a guide to center the system across the root gap

7. Turn the BLUE gas hose on to inflate the bladders and purge the weld zone.

8. Always maintain a consistent flow rate during inflation, purging, and welding.

9.For sizes 2″-36″ BLUE gas hose should transfer inert gas at 30 SCFH (15 LPM) only. For sizes 38″-48″ BLUE gas hose should transfer inert gas at 60 SCFH (28.5 LPM) only.

10. Once a tight seal has been achieved, commence welding

11. After the weld is complete, turn off the gas supply to deflate the bladders. Once the heat zone has sufficiently cooled, remove I-Purge X from the pipe. Be sure to disconnect all gas lines and monitoring equipment.

12. Clean I-Purge X and store in the provided carrying bag when it is not in use

Khang Dong Nam Company specializes in supplying and distributing products of Aquasol I-PurgeX Modular Inflatable Bladder System in Vung Tau and all over Vietnam with high quality and reasonable price. Contact us when you need to buy products or you have any requests for product information

Reviews

There are no reviews yet.